Abstract

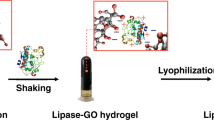

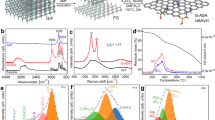

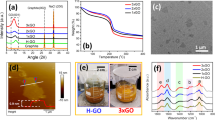

Reversible chemical reactions such as industrial production of esters are governed by the equilibrium law. To improve the productivity of esterification, superfluous reactants and dehydrants are usually used to drive the reaction forward. However, these methods are not only energy intensive but also cause extra difficulty in the separation of final products. Here we propose a photothermal catalysis system based on a sulfonic acid-functionalized graphene oxide aerogel to increase the yield rate of esterification without excess reactants or dehydrants. As a result of local photothermal heating and different molecular bond affinities, the generated products are evaporated out of reactive sites, leading to a local excess of reactants and thereby thermodynamically driving the reaction in favour of ester generation. Specifically, an acetic acid conversion rate of 77% is achieved, which is significantly higher than the theoretical limit of 62.5%. Theoretical analysis reveals its substantial advantage in saving the energy for separating products when applied to the real industrial esterification reaction. Our strategy could find applications in various fields such as thermal catalysis, nitration, acylation and the synthesis of other chemicals.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

All relevant data are included in the manuscript and Supplementary Information. The data that support the findings of this study are available from the corresponding authors upon request.

References

Poliakoff, M. & Licence, P. Green chemistry. Nature 450, 810–812 (2007).

Pöpken, T., Götze, L. & Gmehling, J. Reaction kinetics and chemical equilibrium of homogeneously and heterogeneously catalyzed acetic acid esterification with methanol and methyl acetate hydrolysis. Ind. Eng. Chem. Res. 39, 2601–2611 (2000).

Neumann, K., Werth, K., Martín, A. & Górak, A. Biodiesel production from waste cooking oils through esterification: catalyst screening, chemical equilibrium and reaction kinetics. Chem. Eng. Res. Des. 107, 52–62 (2016).

Konwar, L. J., Wärnå, J., Mäki-Arvela, P., Kumar, N. & Mikkola, J.-P. Reaction kinetics with catalyst deactivation in simultaneous esterification and transesterification of acid oils to biodiesel (FAME) over a mesoporous sulphonated carbon catalyst. Fuel 166, 1–11 (2016).

Buelens, L. C., Galvita, V. V., Poelman, H., Detavernier, C. & Marin, G. B. Super-dry reforming of methane intensifies CO2 utilization via Le Chatelier’s principle. Science 354, 449–452 (2016).

Quílez-Pardo, J. & Solaz-Portolés, J. J. Students’ and teachers’ misapplication of Le Chatelier’s principle: implications for the teaching of chemical equilibrium. J. Res. Sci. Teach. 32, 939–957 (1995).

Liu, B., Hu, F. & Shi, B.-F. Recent advances on ester synthesis via transition-metal catalyzed C–H functionalization. ACS Catal. 5, 1863–1881 (2015).

Nakajima, K. & Hara, M. Amorphous carbon with SO3H groups as a solid Brønsted acid catalyst. ACS Catal. 2, 1296–1304 (2012).

Gong, L. et al. Composite coal fly ash solid acid catalyst in synergy with chloride for biphasic preparation of furfural from corn stover hydrolysate. Bioresour. Technol. 293, 122065 (2019).

Nguyen, V. C. et al. Esterification of aqueous lactic acid solutions with ethanol using carbon solid acid catalysts: amberlyst 15, sulfonated pyrolyzed wood and graphene oxide. Appl. Catal. A 552, 184–191 (2018).

Antunes, B. M., Cardoso, S. P., Silva, C. M. & Portugal, I. Kinetics of ethyl acetate synthesis catalyzed by acidic resins. J. Chem. Educ. 88, 1178–1181 (2011).

Wang, Y., Zhi, H. & Luo, J. A facile and efficient protocol for esterification and acetalization in a PEG1000-D(A)IL/toluene thermoregulated catalyst–media combined systems. J. Mol. Catal. A 379, 46–52 (2013).

Khajavi, S., Jansen, J. C. & Kapteijn, F. Application of a sodalite membrane reactor in esterification—coupling reaction and separation. Catal. Today 156, 132–139 (2010).

Xu, N. et al. A water lily-inspired hierarchical design for stable and efficient solar evaporation of high-salinity brine. Sci. Adv. 5, eaaw7013 (2019).

Hou, D. et al. Hydrophobic nanostructured wood membrane for thermally efficient distillation. Sci. Adv. 5, eaaw3203 (2019).

He, S. et al. Nature-inspired salt resistant bimodal porous solar evaporator for efficient and stable water desalination. Energy Environ. Sci. 12, 1558–1567 (2019).

Zhang, P., Li, J., Lv, L., Zhao, Y. & Qu, L. Vertically aligned graphene sheets membrane for highly efficient solar thermal generation of clean water. ACS Nano 11, 5087–5093 (2017).

Li, Y. et al. 3D-printed, all-in-one evaporator for high-efficiency solar steam generation under 1 sun illumination. Adv. Mater. 29, 1700981 (2017).

Hu, X. et al. Tailoring graphene oxide-based aerogels for efficient solar steam generation under one sun. Adv. Mater. 29, 1604031 (2017).

Yang, M.-Q., Tan, C. F., Lu, W., Zeng, K. & Ho, G. W. Spectrum tailored defective 2D semiconductor nanosheets aerogel for full-spectrum-driven photothermal water evaporation and photochemical degradation. Adv. Funct. Mater. 30, 2004460 (2020).

Li, J. et al. Interfacial solar steam generation enables fast-responsive, energy-efficient, and low-cost off-grid sterilization. Adv. Mater. 30, 1805159 (2018).

Chen, C., Kuang, Y. & Hu, L. Challenges and opportunities for solar evaporation. Joule 3, 683–718 (2019).

Gao, M., Peh, C. K., Zhu, L., Yilmaz, G. & Ho, G. W. Photothermal catalytic gel featuring spectral and thermal management for parallel freshwater and hydrogen production. Adv. Energy Mater. 10, 2000925 (2020).

Wang, W. et al. Simultaneous production of fresh water and electricity via multistage solar photovoltaic membrane distillation. Nat. Commun. 10, 3012 (2019).

Zhou, L. et al. Quantifying hot carrier and thermal contributions in plasmonic photocatalysis. Science 362, 69–72 (2018).

Zhao, Y. et al. Solar- versus thermal-driven catalysis for energy conversion. Joule 3, 920–937 (2019).

Min, X., Zhu, B., Li, B., Li, J. & Zhu, J. Interfacial solar vapor generation: materials and structural design. Acc. Mater. Res. 2, 198–209 (2021).

Li, X. et al. Graphene oxide-based efficient and scalable solar desalination under one sun with a confined 2D water path. Proc. Natl Acad. Sci. USA 113, 13953 (2016).

Zhu, L., Gao, M., Peh, C. K. N., Wang, X. & Ho, G. W. Self-contained monolithic carbon sponges for solar-driven interfacial water evaporation distillation and electricity generation. Adv. Energy Mater. 8, 1702149 (2018).

Wang, Y., Zhang, L. & Wang, P. Self-floating carbon nanotube membrane on macroporous silica substrate for highly efficient solar-driven interfacial water evaporation. ACS Sustain. Chem. Eng. 4, 1223–1230 (2016).

Zhang, P. et al. High throughput of clean water excluding ions, organic media, and bacteria from defect-abundant graphene aerogel under sunlight. Nano Energy 46, 415–422 (2018).

Li, X., Zhu, B. & Zhu, J. Graphene oxide based materials for desalination. Carbon 146, 320–328 (2019).

Guan, W., Guo, Y. & Yu, G. Carbon materials for solar water evaporation and desalination. Small 6, e2007176 (2021).

Wu, Z.-S. et al. 3D nitrogen-doped graphene aerogel-supported Fe3O4 nanoparticles as efficient electrocatalysts for the oxygen reduction reaction. J. Am. Chem. Soc. 134, 9082–9085 (2012).

Xu, Z., Zhang, Y., Li, P. & Gao, C. Strong, conductive, lightweight, neat graphene aerogel fibers with aligned pores. ACS Nano 6, 7103–7113 (2012).

Ghasemi, H. et al. Solar steam generation by heat localization. Nat. Commun. 5, 4449 (2014).

Nakhate, A. V. & Yadav, G. D. Synthesis and characterization of sulfonated carbon-based graphene oxide monolith by solvothermal carbonization for esterification and unsymmetrical ether formation. ACS Sustain. Chem. Eng. 4, 1963–1973 (2016).

Konwar, L. J., Mäki-Arvela, P. & Mikkola, J.-P. SO3H-containing functional carbon materials: synthesis, structure, and acid catalysis. Chem. Rev. 119, 11576–11630 (2019).

Villa, A. et al. Acid-functionalized mesoporous carbon: an efficient support for ruthenium-catalyzed γ-valerolactone production. ChemSusChem 8, 2520–2528 (2015).

Scholz, D., Kröcher, O. & Vogel, F. Deactivation and regeneration of sulfonated carbon catalysts in hydrothermal reaction environments. ChemSusChem 11, 2189–2201 (2018).

Okoye, P. U., Abdullah, A. Z. & Hameed, B. H. Synthesis of oxygenated fuel additives via glycerol esterification with acetic acid over bio-derived carbon catalyst. Fuel 209, 538–544 (2017).

Kuwahara, Y., Kaburagi, W., Nemoto, K. & Fujitani, T. Esterification of levulinic acid with ethanol over sulfated Si-doped ZrO2 solid acid catalyst: study of the structure–activity relationships. Appl. Catal. A 476, 186–196 (2014).

Gilli, P., Pretto, L., Bertolasi, V. & Gilli, G. Predicting hydrogen-bond strengths from acid–base molecular properties. The pKa slide rule: toward the solution of a long-lasting problem. Acc. Chem. Res. 42, 33–44 (2009).

Ma, Y., Wang, Q. L., Yan, H., Ji, X. & Qiu, Q. Zeolite-catalyzed esterification I. Synthesis of acetates, benzoates and phthalates. Appl. Catal. A 139, 51–57 (1996).

Wu, K.-C. & Chen, Y.-W. An efficient two-phase reaction of ethyl acetate production in modified ZSM-5 zeolites. Appl. Catal. A 257, 33–42 (2004).

Said, A. E.-A. A. & Goda, M. N. Green synthesis of bio-ethyl acetate over Egyptian natural red clay as a highly active, selective, and eco-friendly catalyst. J. Chin. Chem. Soc. 67, 567–575 (2020).

Gurav, H. & Bokade, V. V. Synthesis of ethyl acetate by esterification of acetic acid with ethanol over a heteropolyacid on montmorillonite K10. J. Nat. Gas Chem. 19, 161–164 (2010).

Zhong, C., Cao, Q., Guo, L. & Deng, S. Preparation of a coal tar pitch-based solid acid catalyst and its esterification activity in ethyl acetate production.React. Kinet. Mech. Catal. 112, 361–370 (2014).

Ogino, I., Suzuki, Y. & Mukai, S. R. Tuning the pore structure and surface properties of carbon-based acid catalysts for liquid-phase reactions. ACS Catal. 5, 4951–4958 (2015).

Wankat, P. C. Separation Process Engineering (Pearson Education, 2006).

Acknowledgements

We acknowledge the micro-fabrication centre at the National Laboratory of Solid State Microstructures (NLSSM) for technical support. This work is jointly supported by the National Key Research and Development Programme of China (numbers 2021YFA1400700, 2020YFA0406104 and 2017YFA0205700), National Natural Science Foundation of China (numbers 52002168, 12022403, 51925204, 11874211 and 61735008), Science Foundation of Jiangsu (BK20190311), Key Science and Technology Innovation Programme of Shandong Province (2019JZZY020704), Excellent Research Programme of Nanjing University (ZYJH005) and the Fundamental Research Funds for the Central Universities (numbers 021314380184, 021314380190, 021314380140 and 021314380150). J.Z. acknowledges support from the XPLORER PRIZE.

Author information

Authors and Affiliations

Contributions

B.Z. and J.Z. conceived and designed the project. P.Y., H.G., Z.-Y.W., B.L. and J.J. performed the material preparation and characterizations. P.Y. and H.G. contributed to the catalysis experiments. H.F. performed the calculations. B.Z., P.Y., H.G., Z.-Y.W. and J.Z. wrote the manuscript. All the authors discussed the results and commented on the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review information

Nature Sustainability thanks Yu-Wen Chen, Jorge Gascon, Hai-Long Jiang, Ding Ma and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Figs. 1–16, Discussion and Tables 1–2.

Supplementary Video 1

Contact angle between ethanol and SGA.

Supplementary Video 2

Contact angle between acetic acid and SGA.

Rights and permissions

About this article

Cite this article

Yao, P., Gong, H., Wu, ZY. et al. Greener and higher conversion of esterification via interfacial photothermal catalysis. Nat Sustain 5, 348–356 (2022). https://doi.org/10.1038/s41893-021-00841-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41893-021-00841-0

This article is cited by

-

Sustainable conversion regenerated cellulose into cellulose oleate by sonochemistry

Frontiers of Chemical Science and Engineering (2023)

-

Solar thermal swing adsorption on porous carbon monoliths for high-performance CO2 capture

Nano Research (2023)